Miofol® 125AV

Miofol® 125AV is a vapour barrier pure aluminium membrane with LDPE coating. The Miofol® 125AV is reinforced with a polypropylene fabric that makes the membrane resistant to high mechanical loads, even during transport of prefabricated elements. Vapour from the room cannot enter the structure or insulation through Miofol® 125AV.

Gerelateerde producten

-

VASTR® Total Tape

VASTR® Total tape is a single-sided adhesive tape and is universally applicable for membranes and air sealing of the building envelope.

-

VASTR® Aluminium tape

VASTR® Aluminium tape is a reinforced adhesive tape for air, water and vapour tight sealing of overlap seams and repairing damage.

-

VASTR® Butyl tape

VASTR® Butyl tape is a double-sided adhesive sealing tape for adhering membranes to various substrates.

Miofol® 125AV

Miofol® 125AV is a vapour barrier pure aluminium membrane with LDPE coating. The Miofol® 125AV is reinforced with a polypropylene fabric that makes the membrane resistant to high mechanical loads, even during transport of prefabricated elements. Vapour from the room cannot enter the structure or insulation through Miofol® 125AV.

1.50 x 25 m Article No. 3212515026

1.50 x 50 m Article No. 3212515020

Applications

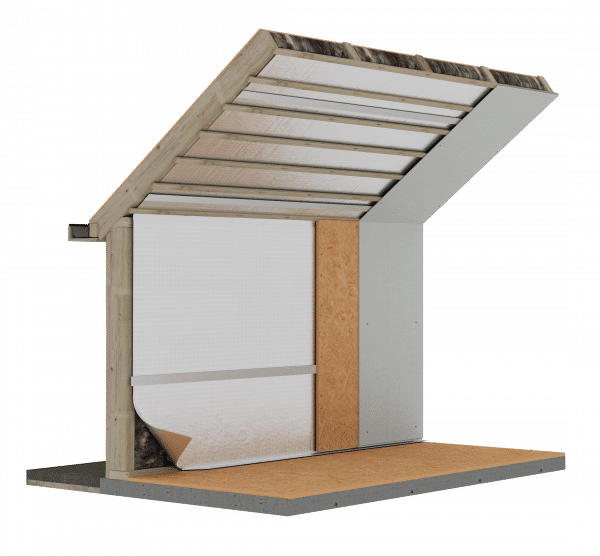

Miofol® 125AV is used as a vapour barrier membrane in floor, facade and roof constructions. The membrane is applied to the warm side of the structure. Due to its vapour barrier property, the Miofol® 125AV is suitable for buildings belonging to climate class 4, such as saunas, swimming pools, bathrooms, gym etc. Miofol® 125AV protects the structure against moisture and provides optimum airtight insulation.

Installation

Apply Miofol® 125AV on the warm side of floor, wall and roof structures. Attach the membrane to the underlying structure using staples. Observe 100 mm at horizontal and vertical overlaps. For optimal vapour control, we recommend taping staples, seams and overlaps with VASTR® Aluminium tape basic. Seal penetrations and connections wind watertight with VASTR® Butyl tape or Tyvek® FlexWrap tape.

Advantages

Vaporproof SD >1500M

High tensile strength and elongation at break

Ideally suited for very humid areas (climate class 4)

Resistant to alkaline substances

Waterproof

Specifications

Weight 125 gr /m²

Fire class F

Water tightness W1

Water vapour resistance Sd >1500 m

Water vapour transmission 0.015 g / m² / day

Tensile strength machine direction 245N / 50 mm

Tensile strength cross direction initially 145N / 50 mm

Elongation machine direction of fracture 14 %.

Elongation cross direction of fracture 13 %.

Nail tear resistance machine direction initial length 160N

Nail tear resistance cross direction initially 200N

Temperature resistance -20°C/80°C