Miofol® 150A

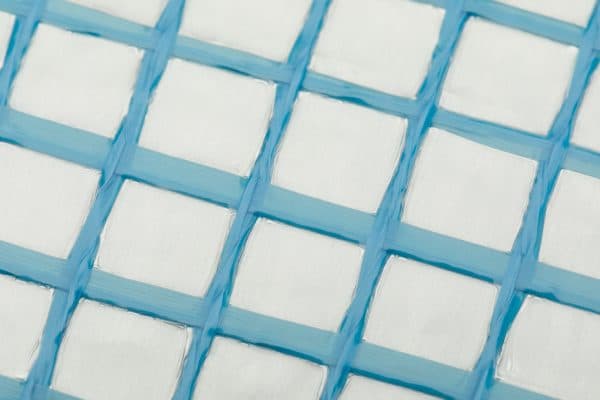

Miofol® 150A is a vapour barrier reflective aluminium membrane reinforced with a polypropylene fabric. The aluminium surface reflects heat radiation which contributes to higher thermal resistance.

Gerelateerde producten

-

VASTR® Total Tape

VASTR® Total tape is a single-sided adhesive tape and is universally applicable for membranes and air sealing of the building envelope.

-

VASTR® Butyl tape

VASTR® Butyl tape is a double-sided adhesive sealing tape for adhering membranes to various substrates.

-

VASTR® Aluminium tape

VASTR® Aluminium tape is a reinforced adhesive tape for air, water and vapour tight sealing of overlap seams and repairing damage.

Miofol® 150A

Miofol® 150A is a vapour barrier reflective aluminium membrane reinforced with a polypropylene fabric. The aluminium surface reflects heat radiation which contributes to higher thermal resistance.

1.50 x 50 m Article No. 6715015000

3.00 x 50 m Article No. 6715030000

Applications

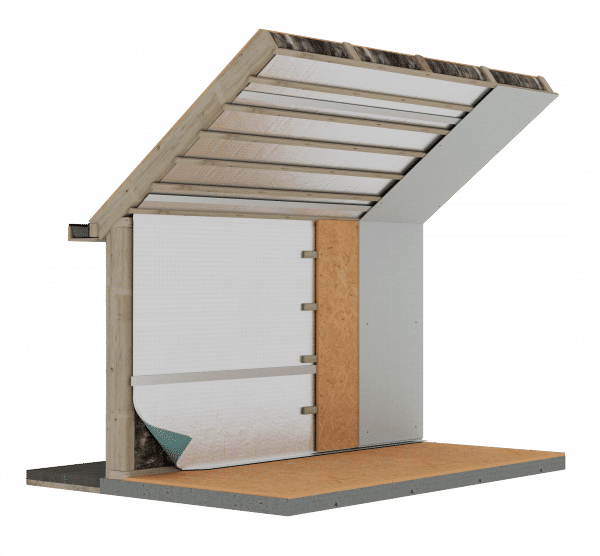

Miofol® 150A is used as a vapour barrier membrane in facade and roof structures. The reflective Aluminium membrane is applied to the warm side (usually the inside) of the structure in combination with a 20mm cavity. The reflection of radiant heat causes the heat resistance to be increased. The Miofol® 150A is reinforced with a polypropylene fabric that makes the membrane resistant to high mechanical loads, even during transport of prefabricated elements.

Installation

Apply Miofol® 150A to the warm side (usually the inside) of the roof and wall construction. The reflective side of the membrane should be applied toward the cavity. Attach the membrane to the underlying structure using staples. At horizontal and vertical overlaps, maintain 100 mm overlap. For optimal vapour barrier construction, we recommend vapour-proofing the fasteners, overlaps, connections and recesses using our VASTR® range.

Advantages

Vaporproof

Reflective

Insulating with air cavity

Extremely high tensile and tear resistance

Available with integrated tape (plus)

Energy saving

Specifications

Weight 150 gr /m²

Fire class F

Water tightness W1

Water vapour resistance Sd >130 m

Water vapour transmission 0.18 g / m² / day

Tensile strength machine direction initially 400N / 50 mm

Tensile strength cross direction initially 400N / 50 mm

Elongation machine direction 15 % at breakage

Elongation cross direction of fracture 18 %.

Nail tear resistance machine direction initial length 405N

Nail tear resistance cross direction initially 430N

Temperature resistance -20°C/80°C

Open construction phase 2 months

R-Value (at 20 mm cavity) 0.57 m² K / W

Emissivity 0.05