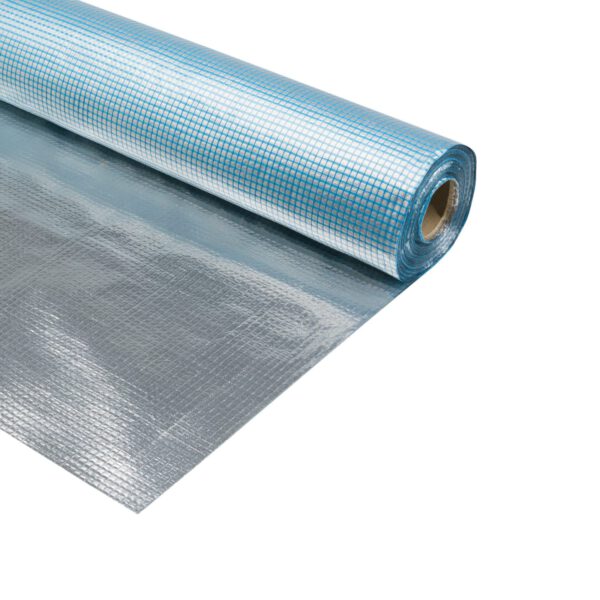

Miofol® 170AG

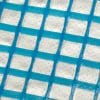

Miofol® 170AG is a micro perforated waterproof breathable aluminium membrane. The back of the membrane is reinforced with a polypropylene fabric over which an LDPE coating is applied. The aluminium side is coated with a UV-stabilized LDPE making the aluminium resistant to alkaline influences. The aluminium surface reflects heat radiation which contributes to higher thermal resistance. The unique microperforation and density of the perforation provide the highest achievable water-repellent of its kind while maintaining high levels of breathability.

Gerelateerde producten

-

VASTR® Butyl tape

VASTR® Butyl tape is a double-sided adhesive sealing tape for adhering membranes to various substrates.

-

VASTR® Aluminium tape

VASTR® Aluminium tape is a reinforced adhesive tape for air, water and vapour tight sealing of overlap seams and repairing damage.

-

VASTR® Total Tape

VASTR® Total tape is a single-sided adhesive tape and is universally applicable for membranes and air sealing of the building envelope.

Miofol® 170AG

Miofol® 170AG is a micro perforated waterproof breathable aluminium membrane. The back of the membrane is reinforced with a polypropylene fabric over which an LDPE coating is applied. The aluminium side is coated with a UV-stabilized LDPE making the aluminium resistant to alkaline influences. The aluminium surface reflects heat radiation which contributes to higher thermal resistance. The unique microperforation and density of the perforation provide the highest achievable water-repellent of its kind while maintaining high levels of breathability.

1.50 x 50 m Article No. 6617015050

2.60 x 50 m Article No. 6617026000

3.00 x 50 m Article No. 6617030050

Applications

Miofol® 170AG is used in facades as a breathable layer on the outside (cold side). The Miofol® 170AG can be used behind masonry facades as well as behind closed facade cladding. The combination of the aluminium layer with the cavity in the facade increases the insulation value. The waterproofing membrane protects the structure and ensures optimal insulation and moisture management.

Installation

Miofol® 170AG is micro-perforated and should therefore be processed free of hard substrates. In facades with a soft substrate, for example mineral wool, the membrane may be applied directly to the soft substrate. The reflective side of the membrane should be applied toward the cavity. Maintain a cavity of 20 mm to 40 mm for optimal thermal resistance. Apply Miofol® 170AG in a shingle fashion. For overlaps, maintain a minimum of 150 mm and a maximum of 200 mm overlap. Apply Miofol® 170AG to the structure using staples. Tape off staples and overlaps with VASTR® Aluminium tape basic. Seal penetrations and connections wind and watertight with VASTR® Butyl tape and/or Tyvek® FlexWrap tape. For optimal water resistance and durability, VASTR® Butyl tape should be applied under the batten.

Advantages

One-sided reflective

KOMO certified

Extremely high tensile and tear resistance

Resistant to alkaline substances

Limits space heating in the summer period

Improving insulation value

Dual function waterproofing vapor permeable and insulating

Unique microperforation

Windproof

Specifications

Weight 170 gr /m²

Fire class F

Water tightness W2

Water vapour resistance Sd 0.32 m

Water vapour transmission 75 g / m² / day

Tensile strength machine direction 410N / 50 mm

Tensile strength cross direction 375N / 50 mm

Elongation machine direction at break 15%

Elongation cross direction at break 14%

Nail tear resistance machine direction initial length 405N

Tear resistance cross direction initial 375N / 50 mm

Temperature resistance -40°C/80°C

Open construction phase 3 months

R-Value (at 1 x 20 mm cavity) 0.57 m² K / W

Emissivity 0.063