Miofol® 200A1

Miofol® 200A1 is a unique composite membrane consisting of woven fiberglass with an aluminium facing developed with Photoncheck-A1 from Thermic Technology. The vapour barrier membrane improves the thermal resistance of the construction and, with fire class A1, is as non-combustible as a brick. The woven structure gives the membrane an extremely high tensile and tear resistance so that that the membrane is not damaged in the construction process.

Gerelateerde producten

-

VASTR® Butyl tape

VASTR® Butyl tape is a double-sided adhesive sealing tape for adhering membranes to various substrates.

-

VASTR® Double-sided tape

VASTR® Double-sided tape is an extremely adhesive two-sided tape for the application of membranes and the air- and windproof sealing of overlap seams.

-

VASTR® Aluminium tape

VASTR® Aluminium tape is a reinforced adhesive tape for air, water and vapour tight sealing of overlap seams and repairing damage.

Miofol® 200A1

Miofol® 200A1 is a unique composite membrane consisting of woven fiberglass with an aluminium facing developed with Photoncheck-A1 from Thermic Technology. The vapour barrier membrane improves the thermal resistance of the construction and, with fire class A1, is as non-combustible as a brick. The woven structure gives the membrane an extremely high tensile and tear resistance so that that the membrane is not damaged in the construction process.

1.35 x 50 m Article No. 6720013500

Applications

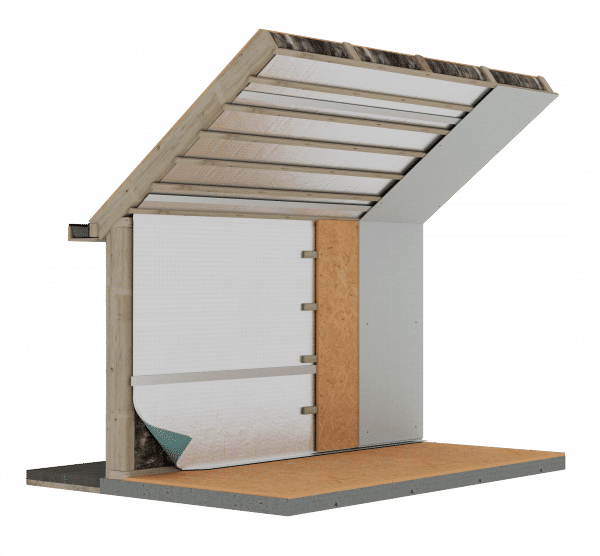

Miofol® 200A1 is used in floor, roof and wall constructions on the warm side of insulation. The vapour barrier aluminium layer provides complete closure of unwanted air leakage and provides protection against vapour pressure from the insulated space. Miofol® 200A1 is a reflection membrane due to the low emissivity of the aluminium surface. Low emissivity results in high reflection of infrared thermal radiation. When the membrane is used in combination with a 20 mm air cavity, the insulation value can be increased to 0.78 m2 K/W.

Installation

Miofol® 200A1 is attached to the warm side of the insulation. The membrane can be fixed with either VASTR® Seal Pro or staples. Process the aluminium side toward you and handle overlaps of 5 to 10cm. Seal overlaps airtight by applying VASTR® Seal Pro, VASTR® Double-Sided tape or VASTR® Butyl tape between overlapping layers. Apply a batten over the membrane that provides the 20mm air cavity. To ensure the secure closure of the attachment points on the batten VASTR® Butyl tape should be applied between the batten and membrane. Seal any staples or perforations with VASTR® Aluminium tape. Penetrations can be sealed air and watertight with Tyvek® FlexWrap tape.

Advantages

Non-combustible (fire class A1)

Fully vapor-proof

Increases the insulation value (up to 0.78 m2 K/W)

UV, heat and corrosion resistant

Reduces unwanted air leakage

Extreme tensile and tear resistance

Specifications

Weight 200 gr /m²

Fire class A1

Water tightness W1

Water vapour resistance Sd > 800 m

Tensile strength machine direction initially 2865 N / 50 mm

Tensile strength cross direction initially 2195 N / 50 mm

Tear resistance machine direction initial length 208N / 50 mm

Tear resistance cross direction initial 302N / 50 mm

Temperature resistance -40°C/80°C

Open construction phase 3 months

R-Value 0.78 m² K / W

Emissivity 0.05