Miofol® 200AK

Miofol® 200AK is a 5-layer self-adhesive vapour barrier aluminium membrane. The polypropylene reinforcement provides high tear and tensile resistance. A solvent-free adhesive coating is applied over the entire surface to apply the membrane without perforation.

Gerelateerde producten

Miofol® 200AK

Miofol® 200AK is a 5-layer self-adhesive vapour barrier aluminium membrane. The polypropylene reinforcement provides high tear and tensile resistance. A solvent-free adhesive coating is applied over the entire surface to apply the membrane without perforation.

1.50 x 50 m Article No. 3220014600

Applications

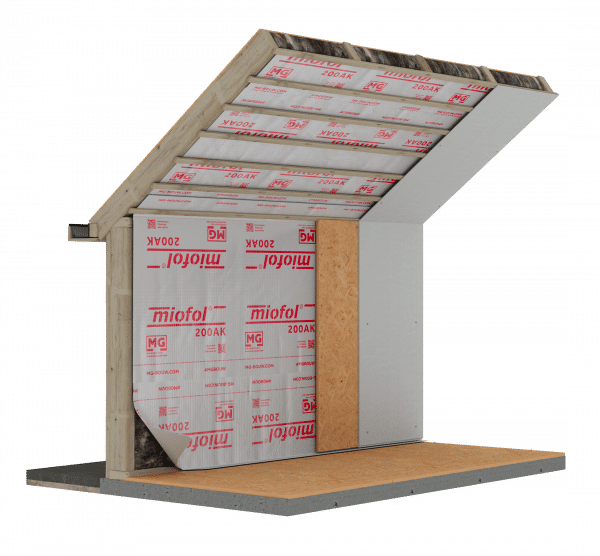

Miofol® 200AK is applied as a vapour barrier layer on the warm side of the insulation. Selfadhesive fastening is particularly suitable on roof structures where the insulation is applied to the vapour barrier membrane (warm roof). The adhesive layer provides an instant windproof attachment without perforations caused by staples. The Miofol® 200AK adheres to both underlayment, OSB and steel roof panels without the need for primer. vapour tight applications on the inside of construction and insulation such as climate class 4 are also among suitable applications.

Installation

Apply Miofol® 200AK on dry dust-free substrates. Remove any sharp parts before applying the membrane. Remove the release membrane on the back and press firmly after attaching. After application, rub the membrane for optimum adhesion and prevention of air bubbles. The adhesive layer of Miofol® 200AK is intended for direct air, vapour and watertight sealing but should always be clamped for permanent fastening under the insulation or a compression lath. Miofol® 200AK minimum 100 mm overlap. Seal any penetrations in the membrane with Tyvek® FlexWrap tape.

Advantages

Lightweight

No primer needed

High tear and tensile resistance due to reinforcement

Quick installation also on steel

Directly waterproof

No tape needed for the overlaps

Vaporproof

Specifications

Weight 200 gr / m²

Fire class E

Water tightness W1

Water vapour resistance Sd >200 m

Tensile strength machine direction 470N / 50 mm initially

Tensile strength cross direction initially 470N / 50 mm

Elongation machine direction of fracture 5%.

Elongation cross direction of fracture 5%.

Nail tear resistance machine direction initial length 100N

Nail tear resistance cross direction initially 140N

Temperature resistance -40°C / 80°C

Open construction phase 3 months