Insulation by reflection

Insulation by means of reflection is already often used in practice, such as in a thermoflask to keep liquids warm for longer or an aluminum blanket for drowning victims who have been in cold water for a long time.

The degree to which a product insulates is expressed in a so-called R-value, or thermal resistance. The higher the R-value, the better the thermal insulation. The R-value is determined by the degree to which heat transfer by conduction, convection and radiation is inhibited.

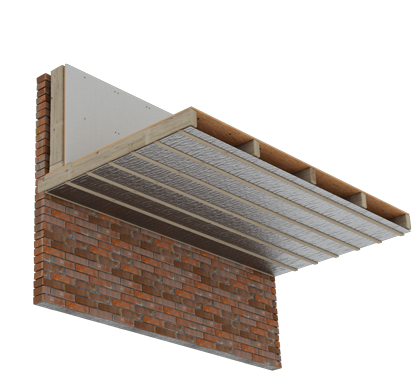

For a material such as concrete, only the resistance to heat transfer by conduction is decisive and convection and radiation in the material itself are not applicable. However, most structures are made up of multiple layers of material, possibly separated by an air cavity. In air cavities, heat transfer by flow and conduction is low and heat loss is mainly determined by radiation. By insulating the air cavity with a reflective foil such as Alkreflex®, high thermal resistances can be realized with a relatively small space usage.

All our reflection films at a glance

Miofol® 210AG is a micro-perforated insulating and reinforced technical construction membrane.

Polytex® 145 AG is a water-repellent and breathable non-woven membrane that features an aluminium top layer.

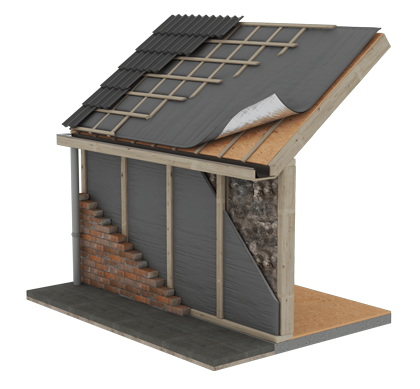

Where is reflection film used?

Reflection films from Meuwissen Gerritsen

For decades, Meuwissen Gerritsen has been developing reflection films that spectacularly improve the insulation value of a construction. This improvement in thermal resistance has been extensively tested by TNO. Thus, the Miofol® 170AG can easily be applied in place of the Miofol® 125G, for example. This also has an advantage in the summer since the reflection film is applied to the outside of the inner cavity wall and blocks incoming solar heat for this purpose. To do this, you ensure that the room stays cool in the summer and save additional costs for air conditioning, for example.

Within the assortment of Meuwissen Gerritsen you can find various reflective films from Miofol®, Alkreflex®, Polytex® and TAFTEX®. Here, the Miofol® 200A1 and 200A1G are the latest innovations in the field of reflective foils because they are completely non-combustible with fire class A. In addition, the Miofol® 125AV, Miofol® 150A and the TAFTEX IN-150 are examples of reflective films that are ideally suited for application on the inside of humid areas with climate class 4.

Applying a reflective film

If you want to apply a reflective film effectively, the reflective side must be at least 20 mm away from the next surface. Does the surface touch the next material then conduction occurs and the insulation is inoperative. Thus, this layer of air is essential for optimal performance of the insulation. A free surface with an emission coefficient of less than 0.1 provides an addition of R-value in a structure of about 0.7. The material thickness of the underlying material may be added to this R-value by the appropriate labda value. This way you can calculate the effectiveness of the reflective film on the R-value of the room yourself. If you are still looking for specialist advice, please contact us.