What is a UV resistant film?

One of the main causes that affect the effectiveness of roof and facade films is exposure to UV radiation. This can occur either during the open construction phase or when the film is applied in a partially open façade or poorly closing tiled roof. A UV resistant film is a vapor-open and waterproof film that resists the effect of UV radiation. Because this film often remains partly visible, even after application, it is always black in color and has no printing. UV-resistant films are wind and watertight but at the same time vapor-open. In this way, the foil ensures that moisture (rain) from the outside cannot affect the structure while moisture from the inside can be drained away. This will protect the structure from mold and wood rot while maintaining the effectiveness of the insulation.

What is the advantage of a UV resistant film?

The main advantage of UV-resistant films is that they retain their effect even when exposed to UV radiation for a long time. In addition, we have UV-resistant films with a fire class B which means they can also be used in wooden facade constructions. Due to the UV-resistant nature, the open processing time of this type of film is often longer than standard films but when long-term durability must be ensured not unlimited. Check the product sheets for the specific film but typically the open processing time is 4 months. This means that the facade or roof finish should be attached up to 4 months after application of the film.

All our UV resistant films at a glance

Polytex® Fassade FR is a breathable and watertight membrane that can be used to protect the insulation layer and construction behind partly open exterior facades.

Tyvek® UV Facade is a watertight and extremely breathable 2-layer non-woven membrane, which is made of HDPE and polypropylene, and is based on Tyvek® Dupont™ technology.

Miotex® Fassade is a watertight breathable membrane, which consists of two layers of polypropylene with a functional micro-porous membrane in between.

Where is UV resistant film used?

When do you use a UV resistant film?

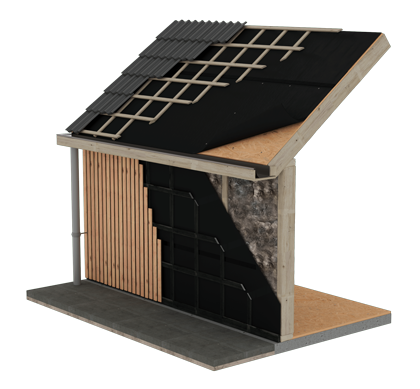

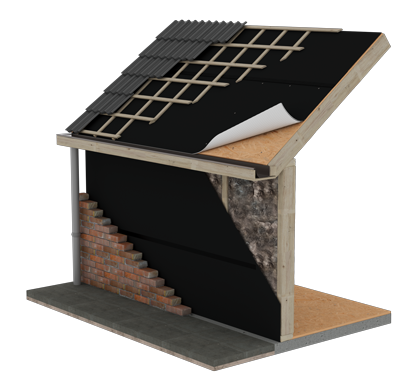

A UV resistant film is applied to the outside of a roof or facade. A UV resistant film is used when the construction has to deal with permanent UV load. This can be the case when roof tiles close poorly such as with old Dutch roof tiles or with a partially open exterior wall. In an open façade system, the façade does not completely close the structure, allowing the space behind the structure to be properly ventilated. But because the façade is not completely sealed, the structure is also exposed to the sun and other weather elements. Therefore, in this case, it is essential that the film used is not only waterproof to stop rain but also that it does not lose its effect when exposed to UV radiation. For this reason, UV-resistant films have a special functional layer to ensure waterproof and vapor-permeable functionality.

How do you apply a UV resistant film?

UV-resistant films are used on the cold side of structures where the black side must always face the outside. The foil should be applied tile by tile with a horizontal overlap of at least 15 cm. To ensure the effectiveness of the film, it is essential to tape the overlaps and staples with special UV-resistant tape such as VAST-R® Facade tape, Tyvek® Facade tape or TAFTEX® Facade tape.

We recommend attaching the UV-resistant foil to the structure with stainless steel staples and then placing the (fabric) battens over the staples. It is important to first attach VAST-R® nail sealing tape or VAST-R® Butyl tape under these (fabric) tiles. This ensures that the screw-hole connection remains watertight and the effectiveness of the film is not compromised.

What do I need to consider with an open façade system?

In the case of an open façade system, it is important that the area between the open sections does not exceed 20% of the total area of the façade. In addition, the space between the gable sections should not exceed 20 mm in width or height. In addition, make sure that there is an air cavity of at least 20 mm between the foil and the cladding. Finally, it is important to allow 10 cm of foil to extend at the bottom, after the bottom line, and then tape it to the underlying structure with the appropriate facade tape.

UV-resistant film at Meuwissen Gerritsen

Within our range we have various vapour permeable and waterproof UV-resistant films of Polytex®, Miotex®, TAFTEX® and Tyvek® available at more than 1100 sales points in the Benelux. Are you looking for the right film for your construction and are you not sure which film is most suitable? View our film guide or contact us for appropriate advice.