to prevent

Energy loss

A vapour control membrane is a film used in the construction to seal an insulated structure from the warm side (inside). The membrane provides an airtight seal so that warm air cannot escape, which directly prevents energy loss. In addition, the membrane also ensures that vapour pressure is held back. That’s why we call it a vapour control membrane.

This is how

a Vapour control membrane works

In an insulated space, it is usually warmer inside than outside. In addition, the air inside usually has high humidity. That is, there is a lot of vapour in the air. With the naked eye, this can only be seen at extreme humidity levels such as after showering in the bathroom. You see that the mirror fogs up or vapour condenses on the windows. When there is a higher humidity and temperature inside than outside then vapour pressure is created.

A vapour control membrane provides resistance so that the warm air stays inside and no energy is lost. In addition, a vapour control membrane ensures that vapour cannot penetrate the membrane in undesirable quantities, thus preventing mold and wood rot.

Discover our vapour control membranes

TAFTEX IN-100 is a vapour control and waterproof membrane composed of two layers of polypropylene.

Miofol® 100S is a vapour control 3 layer COEX membrane with exceptional barrier properties.

Miofol® 125S is a reinforced vapour controlling technical construction membrane. The composite membrane has an extremely long life due to the use of virgin PE.

Miofol® Active is an airtight intelligent vapour control layer with a dual function: vapour controlling in winter and breathable in summer.

AirGuard® Sd5 is a vapour controlling and waterproof membrane composed of DuPont Typar® spunbond and Ethylene-Butyl Acrylate Copolymer.

AirGuard® Sd23 is a vapour controlling and waterproof membrane composed of DuPont Typar® spunbond coated with Polyproplylene.

Miofol VS 2 is a 3-layer floor membrane, including 3 mm PE foam and a blue HDPE top layer.

The Miofol® PE film Pro made of clean, clear quality polyethylene is specifically designed for application in the carpentry and prefabrication industry.

The Miofol® PE film Eco made from recycled polyethylene is specially developed for application in the carpentry and prefabrication industry.

For the inside of

Roof & Wall

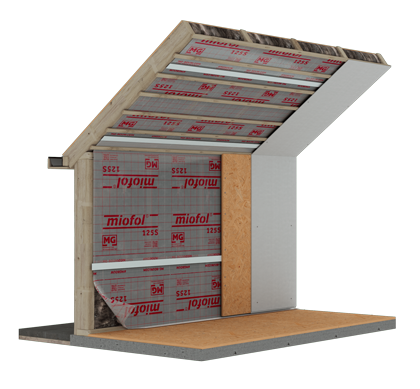

A vapour control membrane can be used for roof insulation or wall insulation. A vapour control membrane is always applied on the inside of the structure, or “warm side” of the insulation. A vapour control membrane provides resistance preventing vapour from escaping. This also ensures that no unnecessary energy is lost. In addition, a vapour control membrane prevents vapour from affecting the construction. This way, you will prevent mold and wood rot. Want to know how to properly install a vapour control membrane? On our website you will find several articles with explanations and installation videos or contact us for appropriate advice.

Therefore, a vapour control membrane

is so important

Prevent condensation

Because warm air can hold more moisture than cold air, condensation occurs when warm air cools to the outside. In an insulated house there is a high humidity of the warm air which can cause condensation in the structure if it is not properly sealed by the proper membrane. This condensation can then cause mold, pests or wood rot. In addition, the performance of the insulation material is significantly reduced when it is damp.

Preserving a structure

Insulating and preserving a structure is hugely important for improving the energy performance of a building or home. It directly contributes to a lower energy bill but above all ensures a reduction in harmful emissions. Insulating a roof or wall can be a substantial investment with installation and finishing.

A fraction of this total cost is the cost of a good vapour control membrane. Therefore, do not skimp on the membrane and choose a membrane with proven performance.

Increase your insulation value

When you decide to insulate a room you can choose different insulation materials. Insulation is nothing more than a layer that reduces the temperature differences between a cold environment (outside) and a warm environment (inside). This usually happens because of low thermal resistance. A low thermal resistance, meaning a high insulation value, means that warm air cannot easily be cooled by the cold environment outside.

However, most insulation materials, such as glass or rock wool, do not counteract air currents that allow warm air to escape. This also happens when insulation boards are not connected airtight. A vapour controle membrane prevents warm air from escaping from inside. In other words, if no vapour control membrane or the wrong insulation membrane is used, warm moist air will escape through the insulation to the outside and this has a negative effect on energy consumption.

Instructional videos

This is how to process a vapor control membrane

Only by properly applying a vapor control membrane will you protect the structure and improve energy performance. In our instructional videos, we explain step by step how to best apply our products.

Installation videos

This is how to process a vapour control membrane

Only by properly applying a vapour control membrane will you protect the structure and improve energy performance. In our installation videos, we explain step by step how to best apply our products.

What is the difference with a

Vapour barrier membrane

There is a very important difference between a vapour control membrane and a vapor barrier membrane.

In the case of a vapour control membrane, the membrane allows vapour to pass through in very small amounts while a vapour barrier membrane is completely sealed. Both membranes are installed on the inside. Depending on the humidity of the room, choose either a vapour control membrane or a vapour barrier membrane. Not sure which membrane you need for your application? Check out the membrane guide, watch our instructional videos or contact us for no-obligation advice.

in which case

Is a vapour barrier membrane better?

In certain structures, it is recommended to use a vapour barrier membrane instead of a vapour control membrane. When the amount of humidity is very high in a bathroom, for example, we speak of climate class 4. In these cases, a vapour control layer will still allow too much vapour to pass through and a higher vapour resistance is necessary. Therefore, in the case of climate class 4, we recommend the use of a vapour barrier film, such as the Miofol® 125 AV or Miofol® 150A.

There are also constructions where the cold side of the insulation is completely sealed. Consider a flat roof with bitumen roofing or EPDM. In these constructions, the cold side is already vapour-tight and an intelligent vapour retarder or climate

membrane such as the Miofol® Active should be used on the warm side of the structure.

Buy your film at

our

dealers

Meuwissen Gerritsen specializes in the development and production of technical building membranes including vapour control membranes, vapour barrier membranes, breathable membranes and much more. With membranes from our well-known A-brands, you are assured of the best quality films. With now 1200 points of sale, you can find our products at building materials stores throughout the Benelux.

Frequently Asked

questions

What is a vapour control membrane?

A vapour control membrane is an insulating film used in building insulation to regulate the spread of water vapour. The membrane is applied to the warm side of the insulation to protect it from condensation and prevent energy waste.

When do you use a vapour control membrane?

A vapour control membrane is used in structures to prevent moisture from entering and condensing in the insulation. This protects the structure from moisture, preventing mold and wood rot, and ensures that the insulation material will not get wet. The use of the right membrane and proper installation are crucial for optimal operation. By preventing moisture problems, a vapour control membrane plays an important role in ensuring the sustainability and energy efficiency of the building.

What is the difference between vapour control membrane and a vapour barrier membrane?

The difference between a vapour control membrane and a vapour barrier membrane lies in its permeability to water vapour. A vapour control membrane inhibits the spread of water vapour, but allows limited vapour transmission. It prevents too much water vapour from penetrating the insulation and is suitable for rooms with climate class 2 and 3 such as homes, offices, schools, etc. A vapour barrier membrane, on the other hand, allows virtually no vapour diffusion and is therefore used in situations where very low vapour diffusion is required. Vapour barrier membranes are therefore used in areas with climate class 4 such as bathrooms, saunas, swimming pools, etc. Both membranes are always applied on the warm side of the insulation to prevent condensation. So the choice between a vapour barrier membrane and vapour control membrane depends on the specific requirements of the building and the level of humidity in the room.

What types of vapour control membrane are there?

There are several types of vapour control membranes where the difference is often mainly in the weight of the membrane. For example, the Miofol® 100S, is 100 grams per m2 and the Miofol 125S is 125 grams per m2. In addition, in some cases the vapour control membrane is reinforced. There is also variable vapour control membrane such as the Miofol® Active which is self-regulating; vapour controlled in the winter and breathable in the summer.

How does a vapor control membrane work?

A vapor control membrane works by limiting vapour diffusion in a building. It creates a barrier that restricts the passage of water vapour from one side to the other. By placing a vapour control membrane on the warm side of the insulation, it prevents warm, moist air from penetrating the insulation from the inside and condensing there. This helps prevent moisture problems such as mold and wood rot. Proper installation of the vapour control membrane is crucial for effective operation.

How thick should a Vapour control membrane be?

The required thickness of vapour control membrane can vary depending on several factors, including the specific application, building codes and climatic conditions of the area. In general, the thickness of vapour control membrane varies between 0.1 mm and 0.3 mm.

When choosing the right thickness, it is important to consider the water vapour diffusion resistance of the membrane. This is indicated by the SD value, which indicates how much resistance the membrane offers to vapour diffusion. The higher the SD value, the less water vapour can diffuse through the membrane.

It is advisable to consult building codes and manufacturer’s recommendations to determine the appropriate thickness of the vapour control membrane for a specific application. Professional advice can also help choose the most appropriate thickness of the membrane based on the specific requirements of the project.

How long does Vapour control membrane last?

A vapour control membrane life can vary depending on several factors, including material quality, installation and environmental conditions. In general, a vapour control membrane is expected to have a service life of 20 to 30 years.

The durability of the vapour control membrane depends in part on its resistance to degradation from exposure to UV radiation, temperature fluctuations, humidity and other environmental influences. It is important to choose the insulation membrane suitable for the specific environmental conditions of the building.

Proper installation is also crucial to the longevity of the membrane. Careful installation without cracks, holes or damage minimizes the risk of moisture infiltration and thus extends the life of the film.

Regular inspection of the membrane is recommended to detect any damage or aging. If there are signs of deterioration, such as cracks, delamination or loss of flexibility, it may be necessary to replace the membrane to maintain the effectiveness of the vapour barrier.

It is advisable to consult the manufacturer’s guidelines for specific information on the expected life of the vapour control membrane being used.